BAKU, Azerbaijan, September 21. As the morning sun reflects on the waters of the Caspian, the massive gates of the Baku Deep Water Jacket Factory (BDWJF) open. Every day, the first steps are taken here in constructing the giant platforms that will rise from the sea. It feels as if every corner of the plant carries traces of Azerbaijan’s oil history.

The birthplace of giants

Founded in 1978 through the foresight of National Leader Heydar Aliyev and operational since 1984, the plant is a unique facility designed to assemble deepwater platforms capable of withstanding the Caspian Sea’s most challenging conditions. Since 2012, the plant has been managed by BOS Shelf LLC and is among the largest construction enterprises in the Caspian. The facility includes extensive workshops (bending, pre-production, production, assembly, and painting), overhead cranes and side bridges for heavy load lifting and barge loading, warehouses, material and technical bases, and crawler cranes capable of lifting to 1,350 tons.

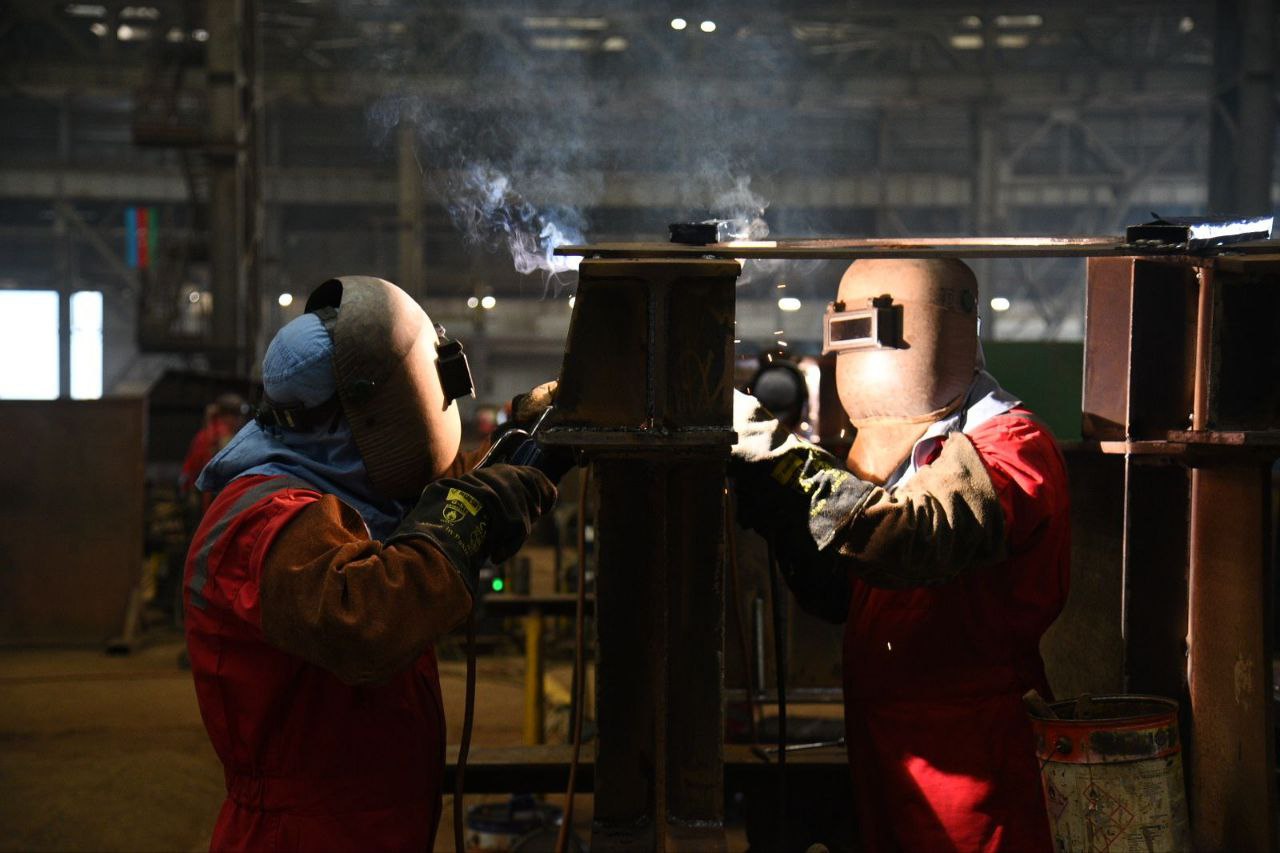

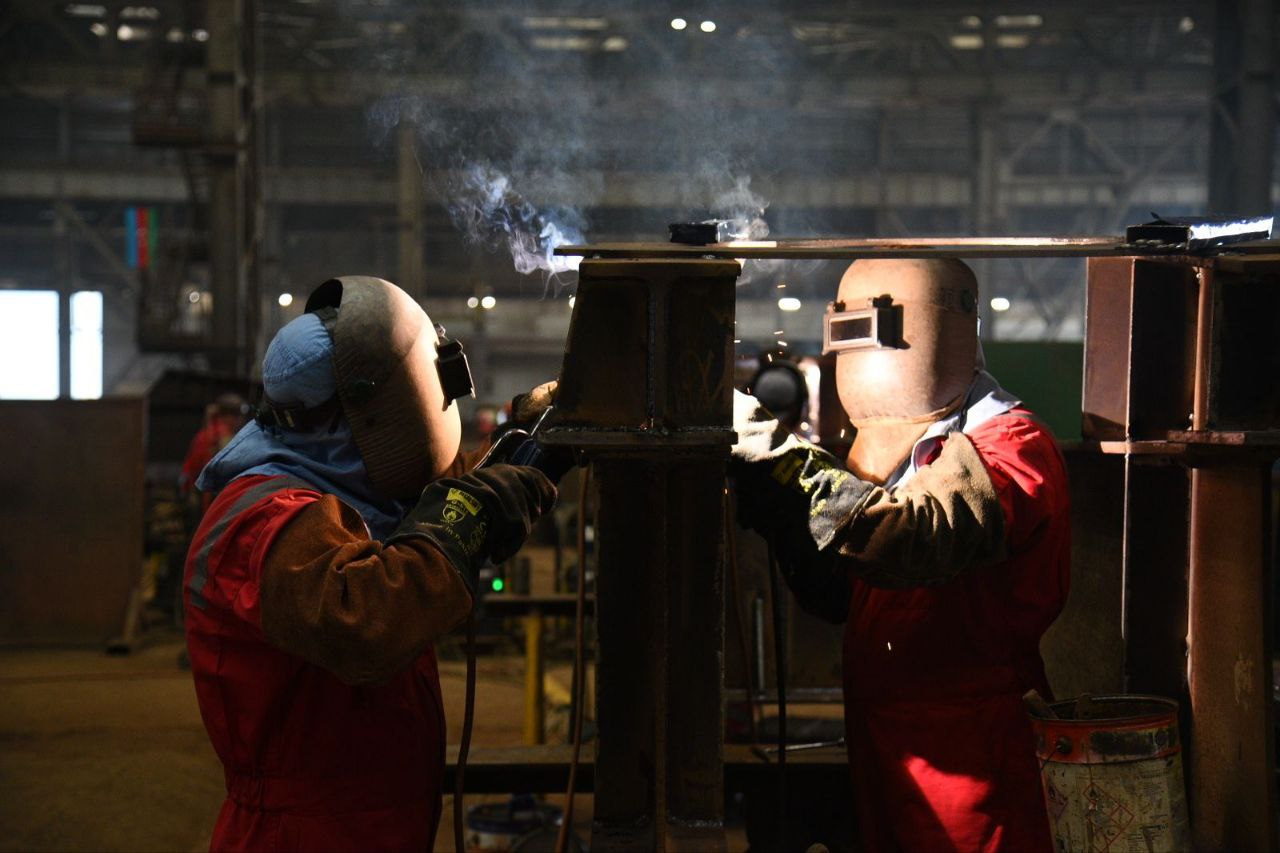

Such facilities are extremely rare worldwide. Thousands of tons of metal are transformed by skilled hands and engineering expertise into the backbone of projects such as Azeri-Chirag-Gunashli, Shah Deniz 2, and Absheron. Today, new technologies are being developed to operate in even deeper waters.

Before stepping into the workshops where these massive structures are born, all visitors undergo an Occupational Health Surveillance and Evaluation Program (OHSEP) training. Instructor Ulvi explains all safety protocols, and protective uniforms are issued. Amid the roar of metal and cranes, one realizes this is not just a plant; it is where the journey to the depths of the Caspian begins.

Through an Engineer’s Eyes

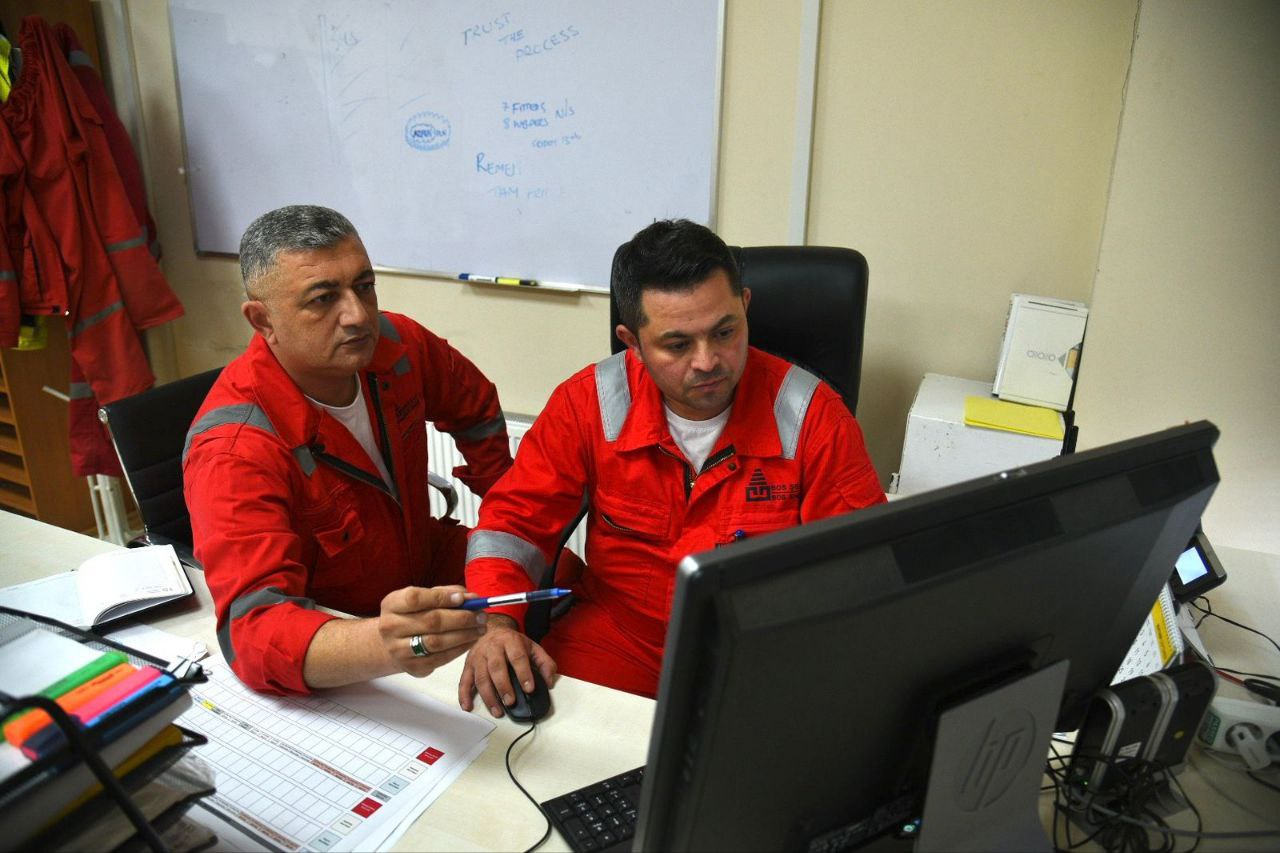

Inside the plant, among the noise, sparks of welding, and rumble of cranes, CNC (Computer Numerical Control) engineer Rufat Abdullayev greets us. He has worked here for 24 years. “Our job is not just to assemble metal. We create robust structures that carry the fate of hundreds of people and billions in investments deep in the sea,” he says.

His day starts at a computer, reviewing calculations, production plans, and daily tasks, then continues in massive workshops with teams of craftsmen. Rufat explains that every platform design accounts for water depth, wave height, wind speed, and even the chemical composition of the water.

“One small mistake could undo years of work,” he adds.

A Day in the Life of a CNC Engineer

Morning: Mechanical stress and durability calculations, review of the production plan and daily tasks, discussions with employees and brigades about their status and challenges, review of technical drawings sent by workshop managers and engineers, and initiation of production.

Afternoon: Supervision of ongoing production in the workshops.

Evening: Reporting completed tasks to workshop managers and setting the task sequence for the next day.

“Think of building a house with a toy constructor as a child. Now you are constructing thousand-ton structures to be installed in the middle of the sea. The only difference is the scale,” Rufat says with a smile.

It’s almost 12 o’clock. This

means it’s lunch time. After chatting with the engineer, we head to

the canteen operating within the plant. There, we are offered a

variety of dishes. Despite the demanding work schedule, every

detail for employees’ comfort is considered. Lunch also serves as

an informal meeting for engineers and craftsmen to discuss the

day’s work. We continue our conversation while tasting the

delicious dishes.

It’s almost 12 o’clock. This

means it’s lunch time. After chatting with the engineer, we head to

the canteen operating within the plant. There, we are offered a

variety of dishes. Despite the demanding work schedule, every

detail for employees’ comfort is considered. Lunch also serves as

an informal meeting for engineers and craftsmen to discuss the

day’s work. We continue our conversation while tasting the

delicious dishes.

“Sometimes we spend more time with our colleagues here than with our families. This plant is not just a workplace; it’s part of our lives,” Rufat says, noting that long hours do not feel tiring thanks to the collective spirit.

“The lunch break is also an essential part of this tremendous work. Without recharging, constructing these massive facilities would be impossible. Clearly, the cafeteria here not only nourishes the body but also sustains the spirit of this remarkable collective,” I note.

After leaving the cafeteria, we

stroll through the plant’s expansive areas. Tons of metal, hoisted

by enormous cranes, are skillfully shaped by craftsmen into

colossal platforms. With every step, it feels as if an energy

bridge for future generations is taking form before your eyes. As

we move into the second part of the day, the noise in the workshops

grows louder. The clanging of iron, the sparks from welding, and

the movement of the large cranes all blend, creating the heartbeat

of the plant.

After leaving the cafeteria, we

stroll through the plant’s expansive areas. Tons of metal, hoisted

by enormous cranes, are skillfully shaped by craftsmen into

colossal platforms. With every step, it feels as if an energy

bridge for future generations is taking form before your eyes. As

we move into the second part of the day, the noise in the workshops

grows louder. The clanging of iron, the sparks from welding, and

the movement of the large cranes all blend, creating the heartbeat

of the plant.

- Rufat, how would you evaluate the work done at the plant during your 24 years of service?

- As part of the BOS Shelf company, we have been constructing support blocks, additional superstructures, underwater infrastructure, pile sets, and support pans for both international and local clients since 2001. Additionally, we have successfully carried out projects aimed at enhancing the performance of drilling platforms, transport barges, and supply bases in support of offshore operations.”

- And what tasks are the master brigades currently working on?

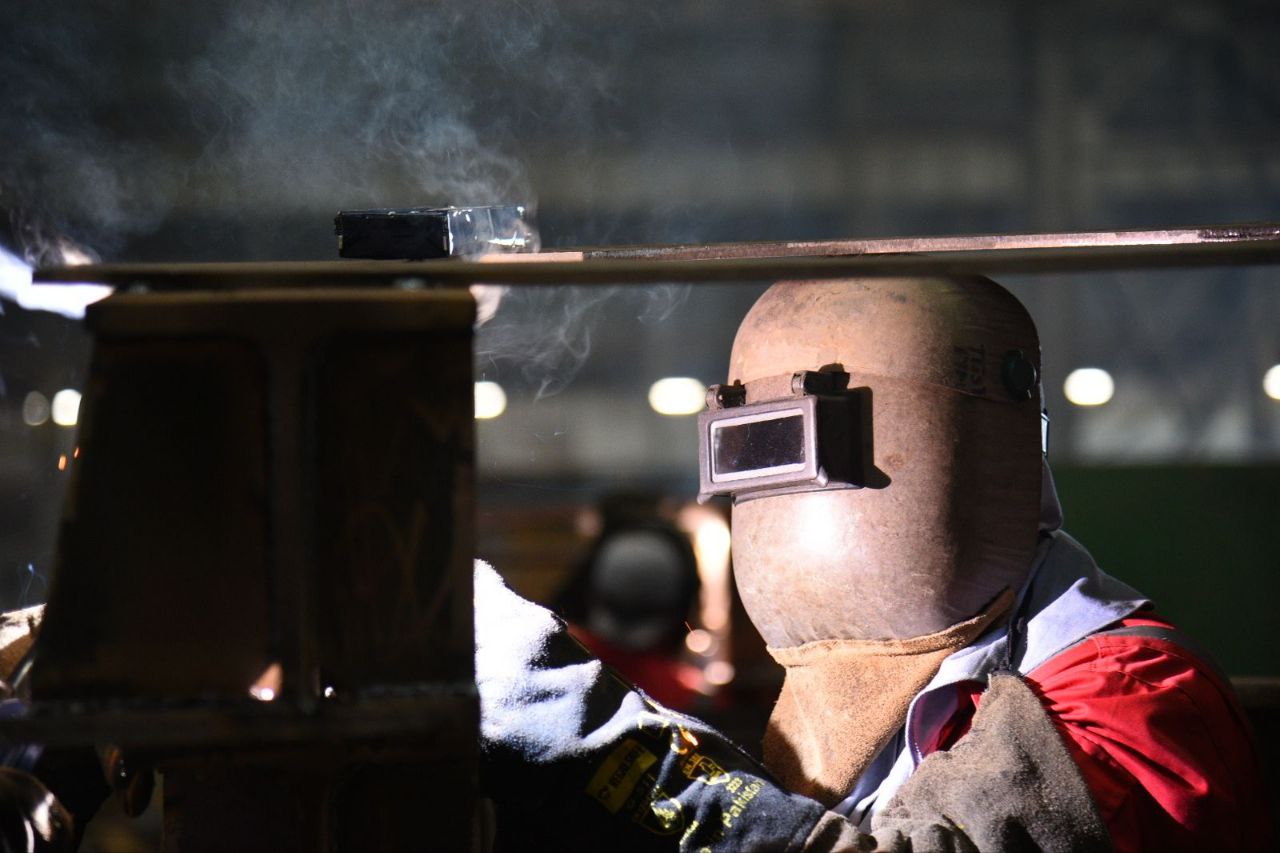

- At present, brigades are cutting metal, welding pipes, and performing essential tasks. Each team works with precision and speed to ensure platforms are reliable in the Caspian.”

As a CNC engineer, Rufat checks

every detail, communicates with staff, and ensures that all

measurements and welds meet the highest standards.

As a CNC engineer, Rufat checks

every detail, communicates with staff, and ensures that all

measurements and welds meet the highest standards.

“Every step demands attention and responsibility because each point affects the safety of platforms weighing thousands of tons,” he emphasizes.

Sometimes he carefully observes a welder’s seam, while at other times he approaches a crane operator to advise on the safest angle for lifting a heavy load. For him, this plant is more than just a workplace; every detail, every piece of metal, is part of a solid platform that will one day stand in the depths of the sea.

He notes that a CNC engineer’s day is divided between the computer and on-site supervision in the workshops.

“Every step requires attention and responsibility, because each measurement and welding point guarantees that the thousand-ton platforms will be reliable in the deep sea,” he emphasizes.

While speaking with us, Rufat also prepares a report for the general manager, detailing the day’s work in the workshops, as well as the plans and schedules for the night shift and the following day.

The colorful diplomas, honorary certificates, and awards hanging on the walls immediately draw attention. They seem to tell the story of the factory’s achievements, and in particular, highlight Rufat’s long-standing dedication.

- Can you tell us a little about these honorary certificates?.

With a smile, Rufat explains that each diploma and award represents years of hard work, dedication to projects, and the collective success of the team. For every employee and engineer, these recognitions serve both as a source of motivation and as vivid reminders of the plant’s history.

I wish him continued success, energy, and new achievements in his future endeavors.

After finishing our tea, we returned to closely observe the production process. In the workshops, workers carry out their tasks; some stop to converse with Rufat, and the atmosphere remains both serious and collaborative.

As the day draws to a close, Rufat makes his final rounds through the workshops, checks the work completed, and sets tasks for the next day. The roar of the plant, the sparks from welding, and the clatter of metal gradually fade into silence.

Our visit to the Baku Deep Sea Jacket Plant concludes. Here, engineers and craftsmen who pay meticulous attention to every detail contribute to the construction of massive structures destined for the depths of the Caspian Sea, seamlessly blending advanced technology with the human spirit of labor and creativity.

Stay up-to-date with more news on Trend News Agency's WhatsApp channel